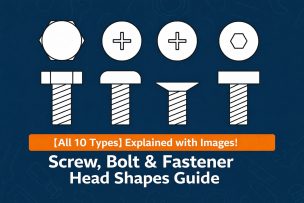

Screws and bolts come in many different head shapes. To select the right fastener, you should choose a head style that matches the application, installation space, appearance requirements, and service environment.

This page explains the major types of screw/bolt head shapes and what each one is typically used for.

Introduction

Fastener “head design” has two separate aspects:

- Head shape (the outside profile of the head)

- Drive/recess shape (how you tighten it: Phillips, slotted, hex socket, etc.)

This article focuses on head shapes only, regardless of the drive/recess type.

Screw & Bolt Head Shapes

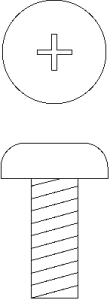

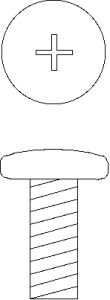

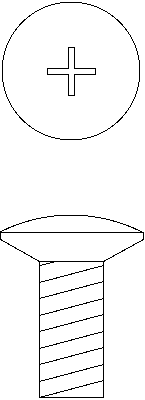

Pan Head

The pan head is one of the most common head shapes. In Japanese, it’s called “nabe” (pan) because it looks like an upside-down pot.

A typical example is the pan head machine screw (often with a Phillips drive). In many cases it has a Phillips recess, and sometimes a combination recess (Phillips + slotted).

Pan-head screws with an internal hex (Allen) drive are generally not used; a similar-looking alternative is the round head socket screw (often called a “button head” or “round socket” type depending on series and standard).

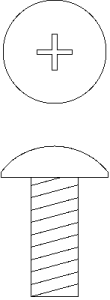

Truss Head

A truss head has a lower head height and a larger head diameter than a pan head.

Because the bearing area under the head is wide, it can clamp workpieces with oversized/elongated holes (clearance holes or slots) without using a washer in many cases.

In terms of strength and holding capability, it is generally similar to a pan head (assuming comparable material/grade and proper tightening).

Bind Head

A bind head is an intermediate head shape—between pan head and truss head in overall size.

The head diameter is larger than pan head but smaller than truss head.

The word “bind” relates to an “edge” or “rim,” and compared with a truss head, the bind head tends to have more thickness with a slightly more pronounced rim-like profile.

Strength and holding capability are generally comparable to pan and truss heads under similar conditions.

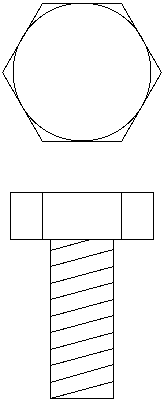

Hex Head

A hex head is the most common bolt head shape. As the name indicates, the head is hexagonal and is tightened using a spanner/wrench or an adjustable wrench.

The typical fastener is the hex bolt, but there are also hex-head types with a Phillips recess or a slotted recess on the top surface, depending on product series and standards.

Hex heads are used across many thread types and standards—including metric and unified threads—and even on some self-tapping/hex washer head screws used for sheet metal and construction.

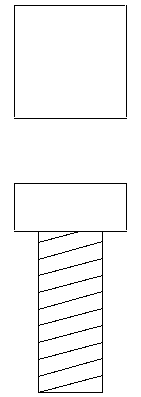

Square Head

A square head is essentially a hex head with the wrenching flats formed into a square.

Because the corners are less likely to round off, square-head fasteners are often used where high tightening force is required—such as steel-frame construction and structural applications.

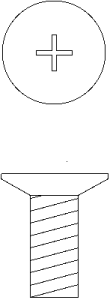

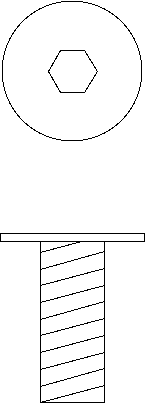

Countersunk (Flat) Head

A countersunk head (flat head) is shaped like a shallow dish, which is why it’s called “sara” (plate) head in Japanese.

Common examples include countersunk screws and countersunk socket screws (flat head socket screws).

One practical point for sizing: many screws and bolts are specified by their length under the head (under-head length). However, countersunk-head fasteners are typically specified by overall length, because the head sits in the countersink.

By machining a matching countersink in the workpiece (a “countersunk seat”), you can design the joint so the head does not protrude above the surface.

Raised Countersunk (Oval) Head

A raised countersunk head (often called an oval head) is a countersunk head with a slightly domed top surface.

This type is frequently used for machine screws. Like a standard countersunk head, it is used with a countersunk seat in the workpiece.

Compared with a fully flat countersunk head, the raised profile can reduce the “depression” at the surface. It’s useful where you want smoother sliding contact or improved appearance at the fastening point.

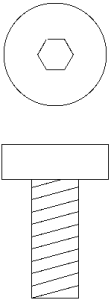

Socket Head Cap (Cap Head)

A socket head cap screw has a cylindrical head with an internal hex (Allen) drive. This is the typical shape associated with “hex socket head cap screws.”

The side of the head often has a knurled or ribbed texture (depending on the standard/series).

Because it supports high tightening torque and is compact, it is widely used for machine elements, tooling, and dies/molds.

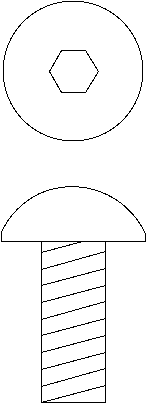

Round Socket Head (Rounded “Cap” Head)

This is a socket-driven head shape with a rounded top profile.

At first glance it may look similar to a pan head, but the key difference is the drive: pan heads are typically Phillips/slotted, while this rounded type uses an internal hex.

Also, the curvature and proportions generally differ slightly from pan or truss heads.

Low Head

A low head is designed with a reduced head height. There are also “ultra-low head” types with even thinner profiles.

Because the head is thin, it is used where there is limited clearance for the head—such as compact machine assemblies or parts where protrusion must be minimized.

A common example is the low head socket cap screw, but there are also low head versions of hex and square head fasteners, depending on product lines.

Conclusion

As you can see, screws and bolts have many head shapes. The best choice depends on the application—required bearing area, installation space, appearance, and service environment.

If you combine head shapes with drive/recess types, the total variety becomes even larger. Please refer to the related pages below as well:

- Screw vs. Bolt vs. “Bisu”: Differences + 24 types (features/uses/shapes)

- Socket Head (Cap Screw) Variations: 8 hex-socket bolt head styles